Description

Description

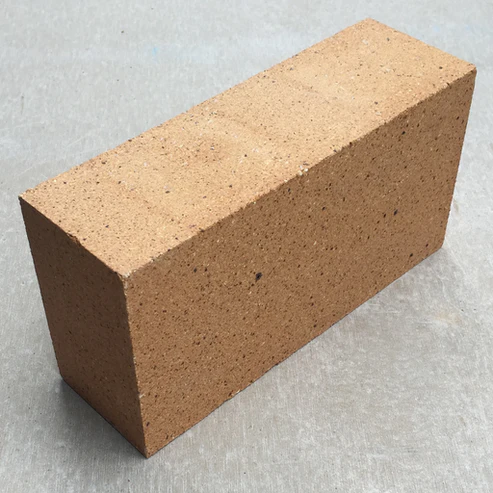

Refractory Bricks are materials designed to withstand high temperatures, chemical corrosion, and thermal shock. Made from raw materials like bauxite, silica, and magnesite, refractory bricks offer excellent compressive strength, heat resistance, and thermal stability. They effectively insulate heat, improve energy efficiency, and extend the service life of equipment. Depending on the application, there are various types of refractory bricks, including high alumina, silica, and magnesite bricks, which are essential for furnaces, boilers, and other high-temperature devices.

| Property | Unit | High Alumina Brick | Silica Brick | Clay Brick | Magnesite Brick | Chrome Brick |

|---|---|---|---|---|---|---|

| Al₂O₃ | % | 48-90 | 0-10 | 30-40 | 0-10 | 5-25 |

| SiO₂ | % | 2-30 | 90-98 | 50-70 | 0-5 | 0-30 |

| Fe₂O₃ | % | ≤ 2 | ≤ 1 | ≤ 2 | ≤ 2 | ≤ 5 |

| CaO | % | ≤ 5 | ≤ 2 | ≤ 5 | ≥ 90 | 20-30 |

| MgO | % | ≤ 5 | ≤ 1 | ≤ 2 | ≥ 90 | 0-15 |

| Cr₂O₃ | % | 0-5 | 0-2 | 0-2 | 0-5 | 45-55 |

| Compressive Strength | MPa | 50-120 | 30-90 | 30-70 | 100-250 | 80-180 |

| Bulk Density | g/cm³ | 2.3-2.75 | 2.3-2.5 | 2.2-2.4 | 2.9-3.0 | 2.8-3.0 |

| Refractoriness | °C | 1700-1800 | 1580-1700 | 1300-1400 | 2800-3000 | 1700-1900 |

| Refractoriness Under Load | °C | 1600-1700 | 1500-1600 | 1300-1400 | 2800-3000 | 1600-1800 |

| Thermal Expansion Coefficient | ×10⁻⁶/°C | 5-8 | 6-9 | 6-7 | 4-6 | 5-7 |

| Thermal Conductivity | W/m·K | 1.0-2.5 | 1.3-2.0 | 1.2-1.8 | 3.5-5.5 | 2.0-3.5 |

| Service Temperature Range | °C | 1600-1800 | 1400-1600 | 1300-1400 | 1800-3000 | 1600-18 |

Request a quote:

Fire bricks and refractory bricks please write down any questions, we will reply as soon as possible and confirm your order.

Refractory Brick Explore the durability and heat resistance of fire bricks (refractory brick) for high-temperature applications in fireplaces, kilns, and furnaces.

Reviews

There are no reviews yet.